The Technology for Special Operations (TSO) electronic workshop in Stellenbosch has a state-of-the-art electronic laboratory focused on developing, prototyping, measuring and testing electronic products for a multitude of applications. This includes research fields such as power and energy management systems (low voltage), analogue, digital and radio frequency (RF) electronics. The laboratory is an anti-static, temperature-controlled environment with conductive floors, electrostatic discharge (ESD) protected workbenches, anti-static chairs and anti-static personal clothing. For the safety of the researchers, an air extraction system extract dangerous fumes from, for example, soldering.

Energy systems

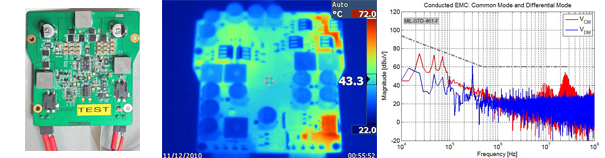

TSO has the capability to design, model and prototype digital controlled switched mode power converters and intelligent battery packs. Test equipment to support these capabilities includes multi-channel high sample rate oscilloscopes, impedance analyser, network analyser, programmable power supplies, various active loads, and computerised simulation software and thermal cameras. TSO also has the capability to perform high frequency conducted electromagnetic compatibility (EMC) modelling design and accurate measurement capabilities.

Analogue electronics

Analogue electronics involve the design, building, packaging and testing of ruggedized analogue electronic functions.

Digital electronics

In digital electronics, the research focus is on embedded microcontrollers, field-programmable gate arrays (FPGAs), code writing and debugging.

Radio Frequency electronics

The electronic workshop is able to test and measure, as well as perform maintenance and repairs on specialised military radios.

Prototyping

In the military environment, electronic products and solutions must be as compact, lightweight and rugged to survive environmental forces. TSO’s electronic engineers and the manufacturing groups work together on projects to ensure an ergonomic design process. One of the focus areas being man-portable equipment. The laboratory has three-dimensional (3D) computer aided design (CAD) suites for custom designs. PCB designs are done in 3D modelling software, and then fused into the mechanical design before the manufacturing process commence. Specialised soldering and inspection equipment combined with a skilled soldering capability enable the lab to populate low volume high density surface mount devices.

In-house measurement

The electronic workshop has sensors, hardware and software modules for automated test equipment (ATE) and the capability to develop software test routines.

Field measurements

Specialised sensors and data recording equipment for underwater explosive measurements are available.

The core focus of this group remains research and development, and every effort is made to ensure that the processes followed are efficient and effective. The success of the research and development in this laboratory draws on the expertise of researchers, engineers and technicians with extensive experience in the defence environment, especially in power generating and management systems.