At the CSIR landward mechanical workshop, researchers develop and package technologies that would evolve from proof of concept, to experimentation, to actual product design. Having a prototype for field testing, takes guesswork out of coming up with solutions to operational needs.

The facility was established in 2000, when Denel’s Mechem research and development division was integrated into the CSIR. It has since been pivotal in a number of successful prototyping projects; One example is the Buffalo mine resistant ambush protected vehicle (which resulted in a licencing venture between the CSIR and General Dynamics Land Systems, an American manufacturer of military vehicles). It was also used in identifying the best option for border patrol vehicles – which meant that commercially-available vehicles were turned into field ambulances, mobile command and control stations, logistical modules and troop carriers.

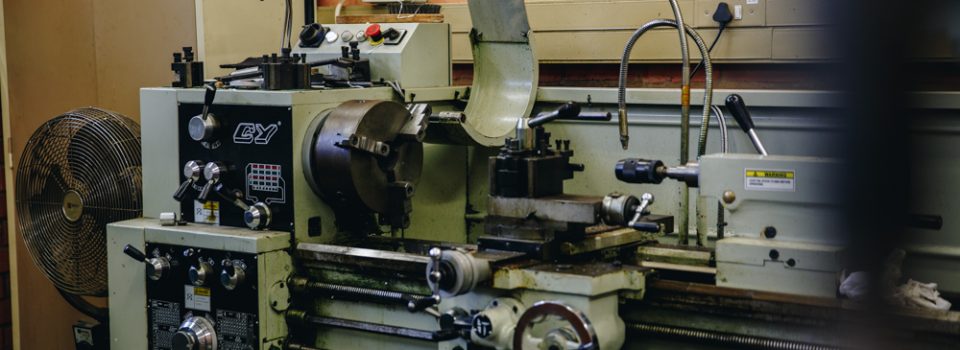

More recently, the workshop produced a test-bed tactical vehicle, which is currently being used to demonstrate enhancements and adaptations ranging from increased situational awareness to unmanned, autonomous vehicle applications. In the workshop, technical staff have access to equipment for advanced prototype manufacturing, metal cutting and fabrication machinery, welding bays, an abrasive water-jet cutter and sophisticated vertical and horizontal computer numerical controlled machining centres.